- In the first stage, the Skovde facility will assemble e-motors

- Plans to establish complete in-house e-motor production by the middle of the decade

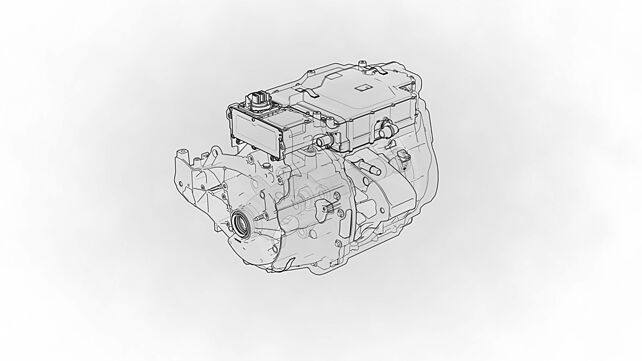

Volvo Cars plan to assemble electric motors at the powertrain plant in Skovde, Sweden. The company plans to establish complete in-house e-motor production by the middle of the decade with an investment of 700 million SEK. Interestingly, the company aims to emerge as a premium electric car company with over 50 per cent fully electric cars by 2025, and the rest would be hybrids.

The Skovde facility has been an integral part of the Volvo Cars story ever since the company’s inception in 1927. Moreover, Volvo Cars has announced its plans to invest significantly in the in-house design and development of e-motors for the next generation of Volvo cars. With the planned investments in Skovde, it now takes the first steps towards in-house e-motor assembly and manufacturing. In its first stage, the Skovde facility will assemble e-motors. While at a later stage, the company intends to bring the full manufacturing process of e-motors in-house into a facility in Skovde.

Bringing the development and production of e-motors in-house will allow Volvo Cars’ engineers to further optimise electric motors and eventually the entire electric driveline in new Volvos. This approach will allow engineers to make further gains in terms of energy efficiency and overall performance.

Design and development of the company’s electric motors takes place in Gothenburg, Sweden, and Shanghai, China. Earlier this year, Volvo Cars opened a new electric motor lab in Shanghai, in addition to ongoing e-motor development in Gothenburg and state-of-the-art battery labs in China and Sweden.

The remaining activities at the Skovde engine plant, focus on the production of internal combustion engines. This will be transferred to a separate subsidiary of Volvo Cars, named Powertrain Engineering Sweden (PES). PES is intended to be merged with Geely’s combustion engine operations, as announced earlier.

![Volvo XC90 [2015-2021] Image Volvo XC90 [2015-2021] Image](https://imgd.aeplcdn.com/272x153/cw/ec/18626/Volvo-XC90-Right-Front-Three-Quarter-164462.jpg?wm=0&q=80)

![Volvo XC60 [2017-2021] Image Volvo XC60 [2017-2021] Image](https://imgd.aeplcdn.com/272x153/cw/ec/26783/Volvo-XC60-Exterior-114592.jpg?wm=0&q=80)

![Volvo XC90 [2015-2021] Right Front Three Quarter Volvo XC90 [2015-2021] Right Front Three Quarter](https://imgd.aeplcdn.com/199x112/cw/ec/18626/Volvo-XC90-Right-Front-Three-Quarter-164462.jpg?wm=0&q=80)

![Volvo XC90 [2015-2021] Right Front Three Quarter Volvo XC90 [2015-2021] Right Front Three Quarter](https://imgd.aeplcdn.com/199x112/ec/45/72/18626/img/m/Volvo-XC90-Right-Front-Three-Quarter-52850_ol.jpg?v=201711021421&q=80)

![Volvo XC90 [2015-2021] Right Front Three Quarter Volvo XC90 [2015-2021] Right Front Three Quarter](https://imgd.aeplcdn.com/199x112/ec/45/72/18626/img/m/Volvo-XC60-Right-Front-Three-Quarter-51459_ol.jpg?v=201711021421&q=80)

![Volvo XC90 [2015-2021] Steering Wheel Volvo XC90 [2015-2021] Steering Wheel](https://imgd.aeplcdn.com/199x112/cw/ec/18626/Volvo-XC90-Steering-Wheel-76968.jpg?v=201711021421&q=80)

![Volvo XC90 [2015-2021] Interior Volvo XC90 [2015-2021] Interior](https://imgd.aeplcdn.com/468x263/cw/ec/18626/Volvo-XC90-Interior-76972.jpg?v=201711021421&q=80)