- This is the only production line where both MEB and MQB platform vehicles can be built alongside each other

- Production of the first MEB-based Skoda vehicle is set to start before the end of this year

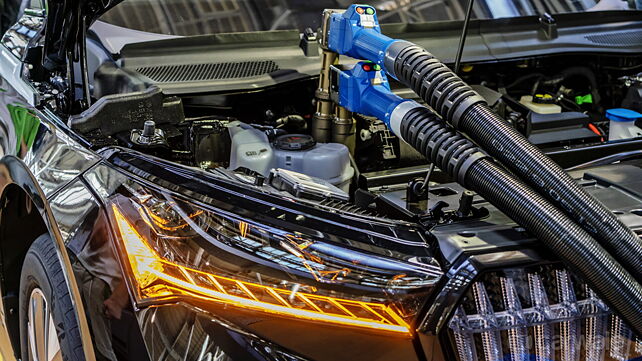

Skoda Auto has completed the conversion of an existing production line at its main factory in Mlada Boleslav (Czech Republic) for MEB vehicles (electric platform).

Modifications have been carried out to cater for the weight of all-electric vehicles and their assembled components. There are auxiliary robots installed for handling the heavy battery packs, and lots of security measures have been taken for it.

The company invested 32 million euros in the work that included structural changes to the factory building, as well as modifications to the conveyor technology and final assembly line.

It is now the only line in the entire Volkswagen Group on which vehicles based on the MEB modular electric car platform and the MQB modular transverse matrix can be built alongside one another.

This means that the all-electric Skoda Enyaq iV, the Octavia, and the Karoq compact SUV all roll off the same production line at the Mlada Boleslav factory in the Czech Republic.

Michael Oeljeklaus, Board Member, Production, Skoda Auto, said, “The conversion of the Skoda Enyaq iV production line in Mlada Boleslav allows us to manufacture vehicles based on the MEB and MQB platforms in parallel. This is a unique concept across the entire group. It enables us to produce between 250 and 350 units of the Enyaq iV per day, at our main factory with total flexibility. This means we can react to the respective market demand without delay whilst ensuring that the line runs at full capacity at all times.”