- First prototype carbon fibre MonoCell shipped from innovation and production centre in Yorkshire to the McLaren Production Centre (MPC) in Woking, Surrey

- The in-house developed tub forms the main structure of McLaren’s cars and will be involved in crash testing

- McLaren Sportscars and Supercars will go hybrid by 2024

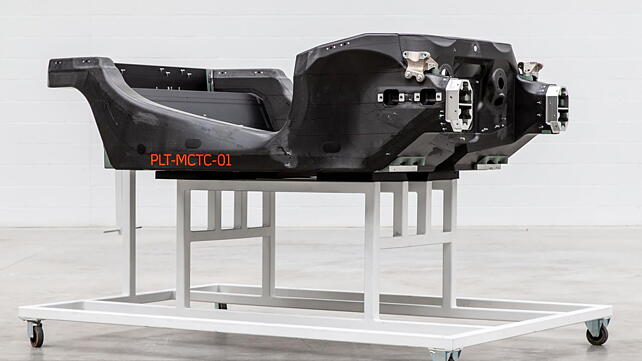

Globally popular performance car manufacturer, McLaren has shipped its first prototype carbon fibre MonoCell, the tub that forms the main structure of McLaren’s cars, from the new £50m innovation and production centre in Yorkshire to the McLaren Production Centre (MPC) in Woking, Surrey. The carbon fibre tub codenamed ‘PLT-MCTC - 01’ - which stands for ‘Prototype Lightweight Tub, McLaren Composites Technology Centre - 01’, will be involved in stringent crash testing duties.

The McLaren Composites Technology Centre (MCTC) in Yorkshire was opened last year by the Duke and Duchess of Cambridge alongside HRH Prince Salman bin Hamad Al Khalifa, the Crown Prince of Bahrain. The technology centre is a part of McLaren’s ambitious plans to increase the rate of innovation of its popular lightweight carbon fibre chassis that are at the heart of all its cars. The new carbon fibre tub will help the designers and engineers to shave some off as the company develops its next generation of vehicles as part of the ambitious Track25 business plan.

Interestingly, McLaren sportscars and supercars will go hybrid by 2024. Therefore, it becomes important to have a reliable lightweight tub as the hybrid powertrains will be inadvertently heavier than the traditional petrol powertrain. The MCTC currently employs around 60 people which will rise to over 200 when full production commences in 2020.