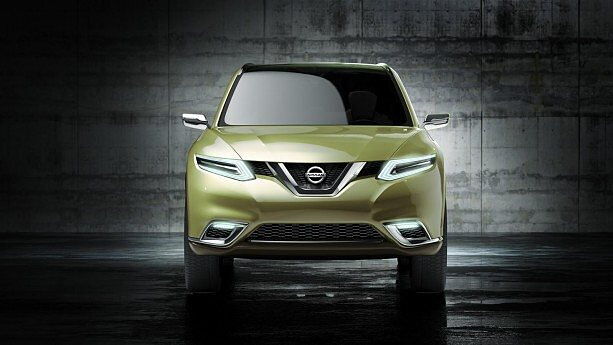

Renault-Nissan alliance announced the introduction of CMF (Common Module Family) engineering architecture, yesterday, to alter the manufacturing process of its line-up. The new engineering architecture will be used on a number of models in both, the Renault and Nissan line up from 2013 and the X-Trail will be the first of many to be manufactured using this concept. Renault-Nissan intends to implement the new manufacturing technique to its entire cast by 2020.

The Common Module Family architecture essentially follows a philosophy similar to Volkswagen’s MQB platform, allowing the manufacturer to share the assembly of modules such as the engine bay, front underbody, rear underbody, electrical and electronic architecture and cockpit among its various models assisting the manufacturer to keep the development and production costs in check. The CMF architecture will help the alliance to introduce rationality across its disparate platforms and help the company to manufacture diverse models at the same facility, further saving costs.

The process will involve modifications to their production facilities to incorporate the modified assembly pattern. As part of the progression, the assembly of all motors and transmissions will be positioned uniformly. As the X-Trail is not currently manufactured in India, NMIPL (Nissan Motor India Private Limited) plant in Chennai will not be in the first short-list to get the transformation.

The idea signs a return to basic principles of mass production in an industry where over the last 100 years the manufacturing process has reached high levels of complexity. By creating a standardised, interchangeable set of parts from which to build a variety of cars, vehicles can now be manufactured at a considerably quicker pace. But it beckons to be asked, will our cars fail to have the uniqueness that their older generations so beautifully flaunt.

![Nissan X-Trail [2009-2014] Image Nissan X-Trail [2009-2014] Image](https://imgd.aeplcdn.com/272x153/cw/cars/discontinued/nissan/x-trail-2009-2014.jpg?q=80)

![Nissan X-Trail [2009-2014] Interior Nissan X-Trail [2009-2014] Interior](https://imgd.aeplcdn.com/640x348/ec/92/71/10486/img/l/Nissan-X-Trail-Interior-17098.jpg?v=201711021421&q=80)